Mounting the Water Blocks

All the parts are finally here, so it's time to dive in on mounting the water blocks! I've already had the CPU block on before, so that only took a few minutes.

Now we're finally on to the butt-clenching parts of this build. Mounting the GPU block is going to be pretty scary... Even though I've worked with hundreds of PCB's, this is the most valuable one I've been personally liable for.

Anyhew, I watched a few random youtube videos on how to do this without completely destroying my card, and just dove right in.

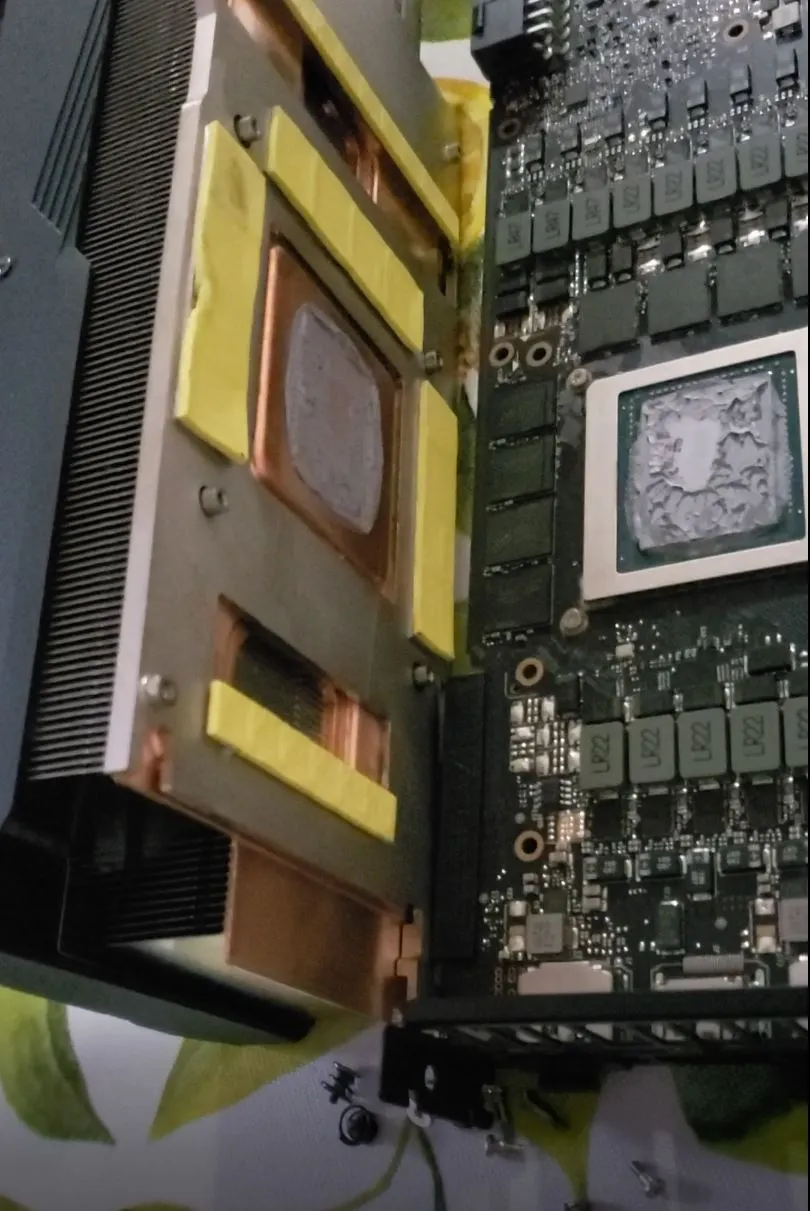

I unbolted the backplate, and tore the heatsink off:

Now we're finally on to the butt-clenching parts of this build. Mounting the GPU block is going to be pretty scary... Even though I've worked with hundreds of PCB's, this is the most valuable one I've been personally liable for.

Anyhew, I watched a few random youtube videos on how to do this without completely destroying my card, and just dove right in.

I unbolted the backplate, and tore the heatsink off:

Cleaned the GPU package:

Cleaned the GPU package:

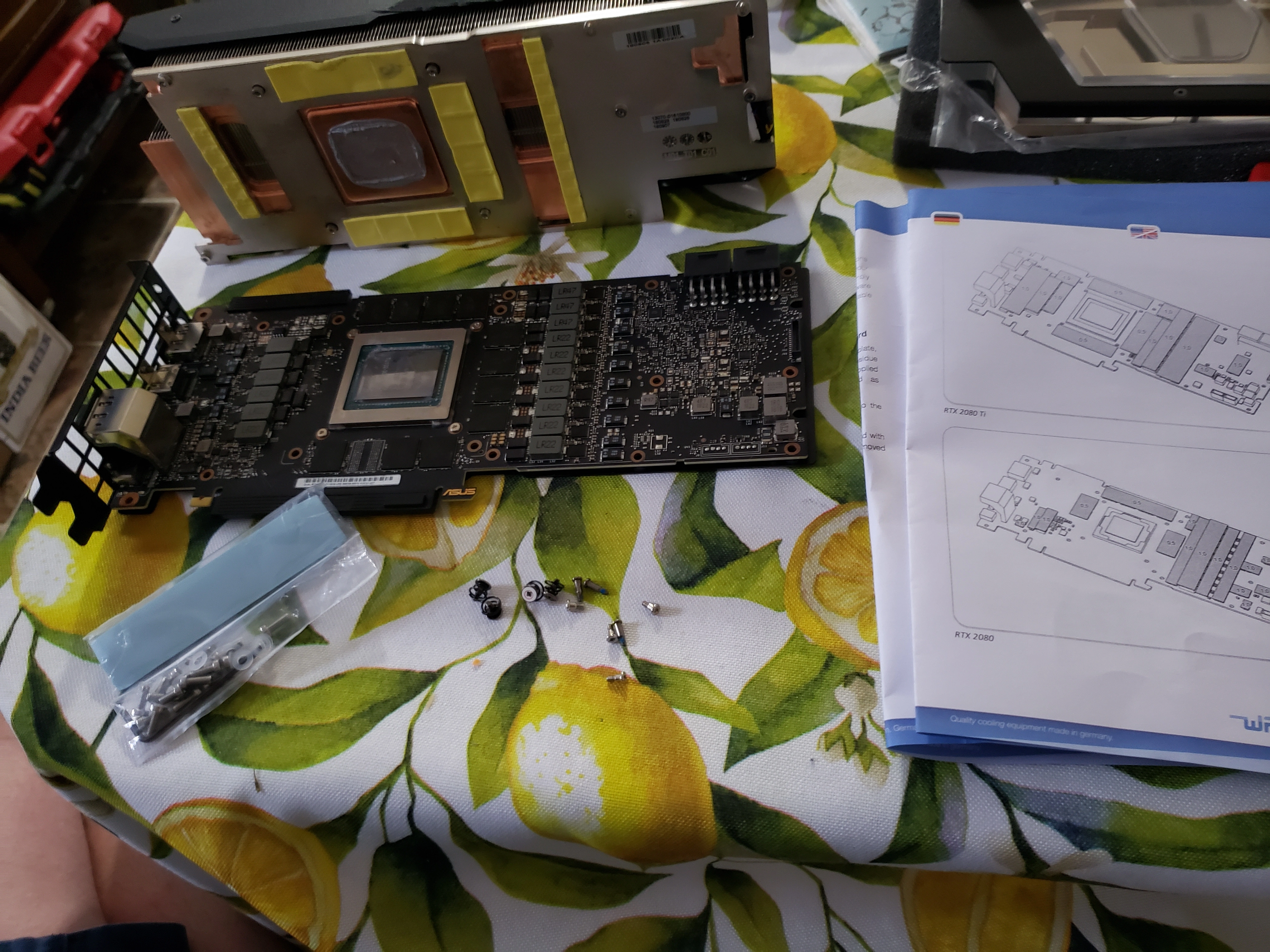

Removed the backplate:

Removed the backplate:

Spent a solid half hour figuring out where to put the thermal pads...

Figured it out, got the block aligned with the PCB and ready to flip onto it, applied some paste of course:

Figured it out, got the block aligned with the PCB and ready to flip onto it, applied some paste of course:

And finally, finished the job! I won't know if it worked for quite some time though...

And finally, finished the job! I won't know if it worked for quite some time though...

PETG Bending

Now I finally get to start planning my bends! I don't think there's really a methodology out there on how to do this, so I'm just going to dive in and give it my best shot and hopefully the result is nice.

I think the first step is installing all the components with water I/O to start trying to visualize where the runs should go, so I installed the distro plate, radiator and GPU into the motherboard and sized it all up, and setup what will be my first attempt at a bending workstation. I left the distro plate loose for now so I can adjust it's position as I decide where I want the bends to go.

Next it's time mess up a few bends so I can learn how to do it! I bought 2x as much tube as I'd actually need so I should have lots of extra to work with. I'd love to think I'll be able to do this first try, but yeah, probably not.

So, I grabbed a bowl of soapy water, a piece of tube and my heat gun and went to town. Almost all the bends I think I'll need to do are 90 degrees so I'm just going to try to do that first. I'll try as close to the end as I can to fit in lots of mistakes on a single piece of waste. Here's my first result:

Next it's time mess up a few bends so I can learn how to do it! I bought 2x as much tube as I'd actually need so I should have lots of extra to work with. I'd love to think I'll be able to do this first try, but yeah, probably not.

So, I grabbed a bowl of soapy water, a piece of tube and my heat gun and went to town. Almost all the bends I think I'll need to do are 90 degrees so I'm just going to try to do that first. I'll try as close to the end as I can to fit in lots of mistakes on a single piece of waste. Here's my first result:

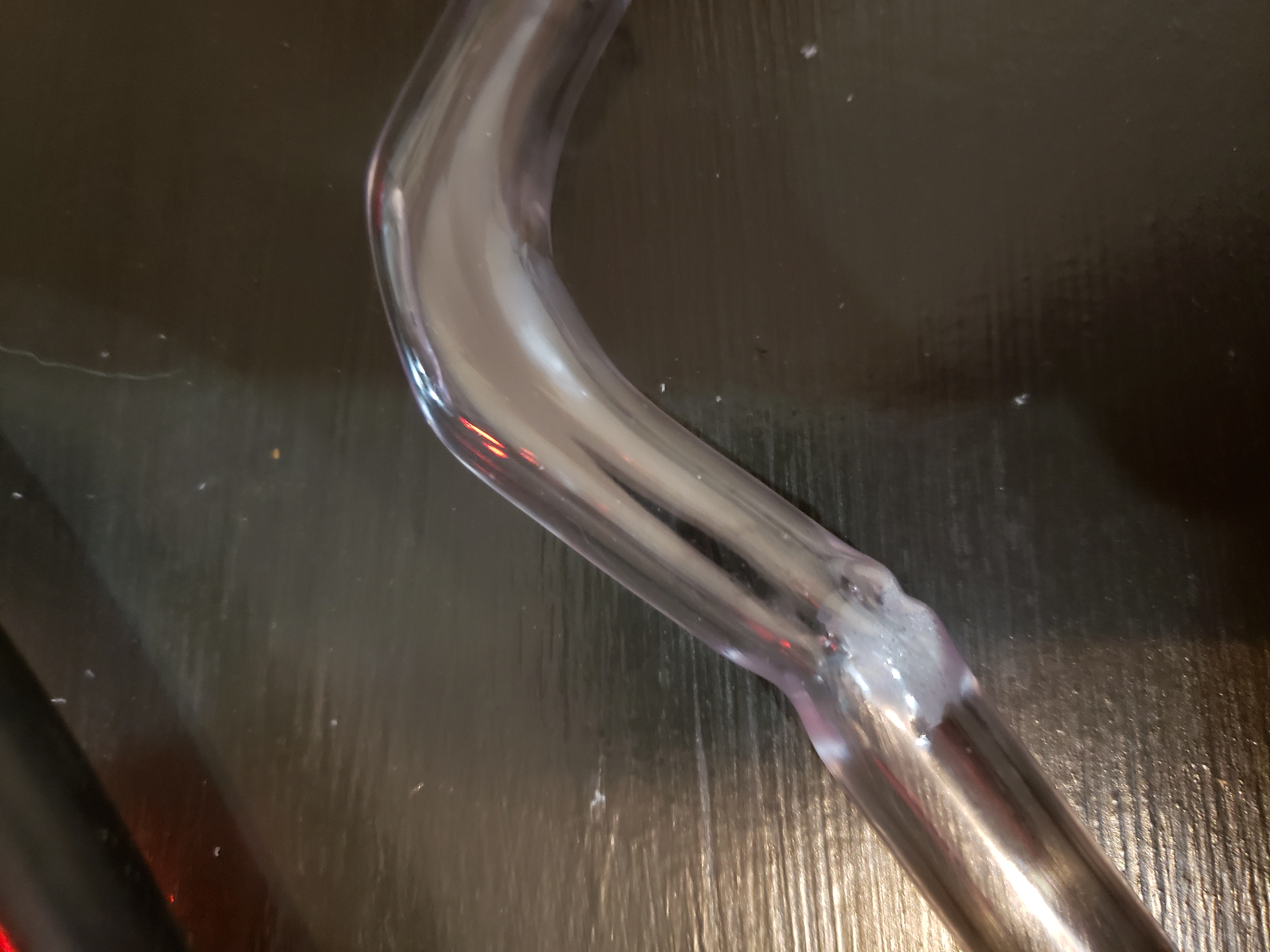

As you can see, I tried twice. The first time, I started bending while it was too cold and when it started to cave in I pulled on it to try to fix it and made it a lot worse. I ended up cooling it down without it ever really bending. The second bend was better, but it was overall too cold resulting in a flat spot on the top and a dimple in the bottom, but also it was locally too hot with bubbles forming in the material.

I adjusted the temperature of my heat gun and adjusted how far from the heat I was moving the material, and here's my third attempt:

As you can see, I tried twice. The first time, I started bending while it was too cold and when it started to cave in I pulled on it to try to fix it and made it a lot worse. I ended up cooling it down without it ever really bending. The second bend was better, but it was overall too cold resulting in a flat spot on the top and a dimple in the bottom, but also it was locally too hot with bubbles forming in the material.

I adjusted the temperature of my heat gun and adjusted how far from the heat I was moving the material, and here's my third attempt:

This time, I nailed the actual bending, but as you can see it's past the 90 degree mark. I actually used a 90 degree jig from thermaltake - I assumed it would result in a perfect 90 degree bend. Either I misused the product, or the product sucks. Either way, I decided I would just eye the angles next time.

This time, I nailed the actual bending, but as you can see it's past the 90 degree mark. I actually used a 90 degree jig from thermaltake - I assumed it would result in a perfect 90 degree bend. Either I misused the product, or the product sucks. Either way, I decided I would just eye the angles next time.

Just eyeing the angle, I think I hit a lot closer to a perfect 90 degrees! I'm also very happy with how the material is bending, here's the process I've come up with to get perfect bends:

Just eyeing the angle, I think I hit a lot closer to a perfect 90 degrees! I'm also very happy with how the material is bending, here's the process I've come up with to get perfect bends:

- Turn on the heat gun and let the temperature regulate to 250 degrees and set the airflow to the mid-way point

- Soak the silicon insert in soapy water and insert it into the tube

- Note where you want the middle of the bend to be

- Hold the material about 2 inches above the heat-gun, spin the tube and move it length-wise over the heat back and forth over the heat about 5 inches above and below where the bend is going to be

- Release one end of the tube every now and then to see if it's starting to bend

- Once the material is almost hot enough, it'll start to sag

- You'll end up heating one side a little more than another, and that side is where the bend will start moving towards

- Keep heating the tube, but also slowly (VERY SLOWLY) start allowing the tube to bend under it's own weight towards the natural direction of the bend

- Apply more heat to the outer-radius of the bend than the inner

- Keep slowly bending it, apply heat until you've reached about the correct angle

- Take the tube away from the heat and use some sort of guide to make a last few adjustments

- As it cools constantly make minor adjustments to the bend to get it right where you want it

- You can re-apply heat if you need to make adjustments, it's way easier to do this now than later if you can manage to get the tube about where it's going to go in the rig

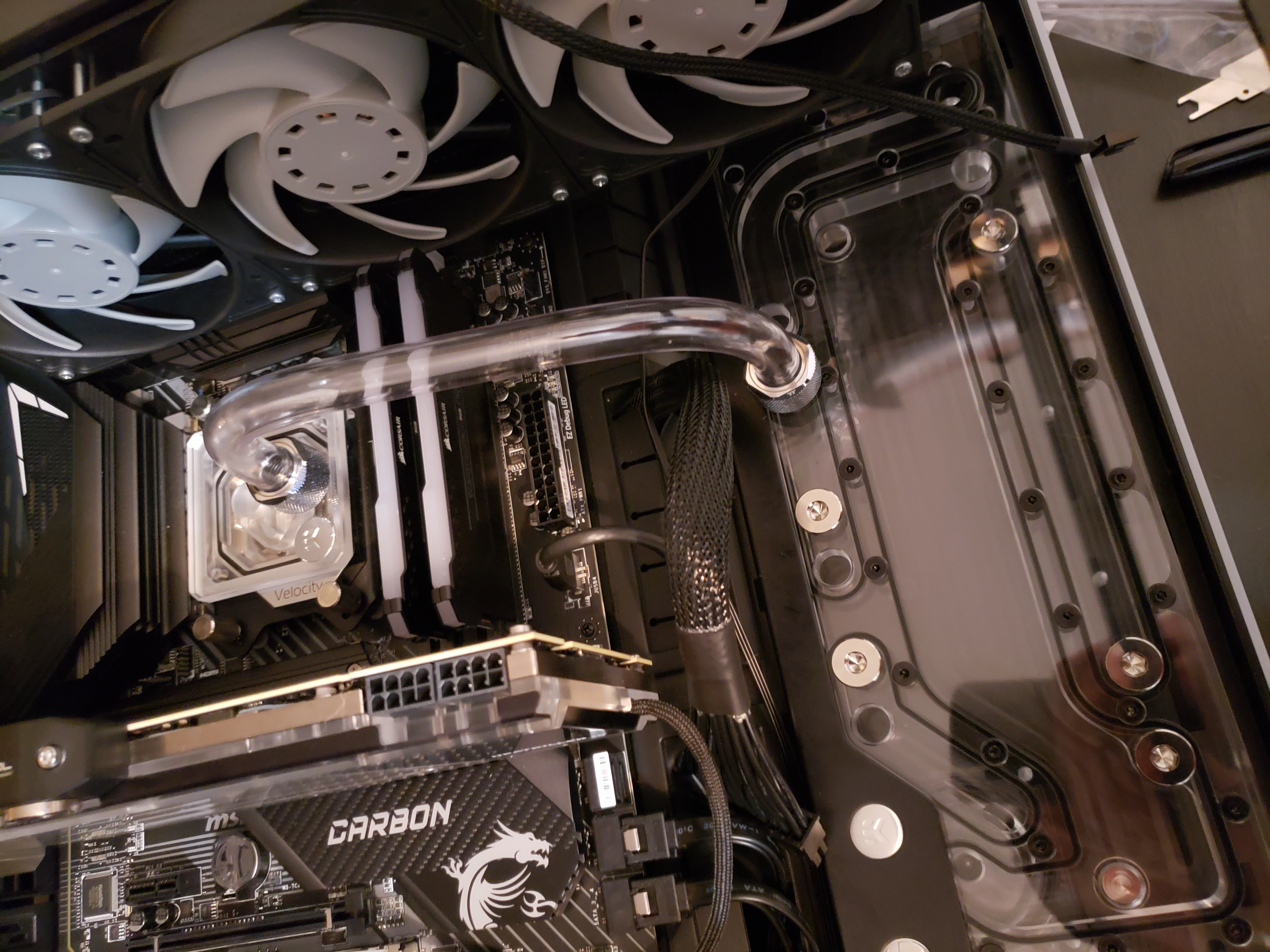

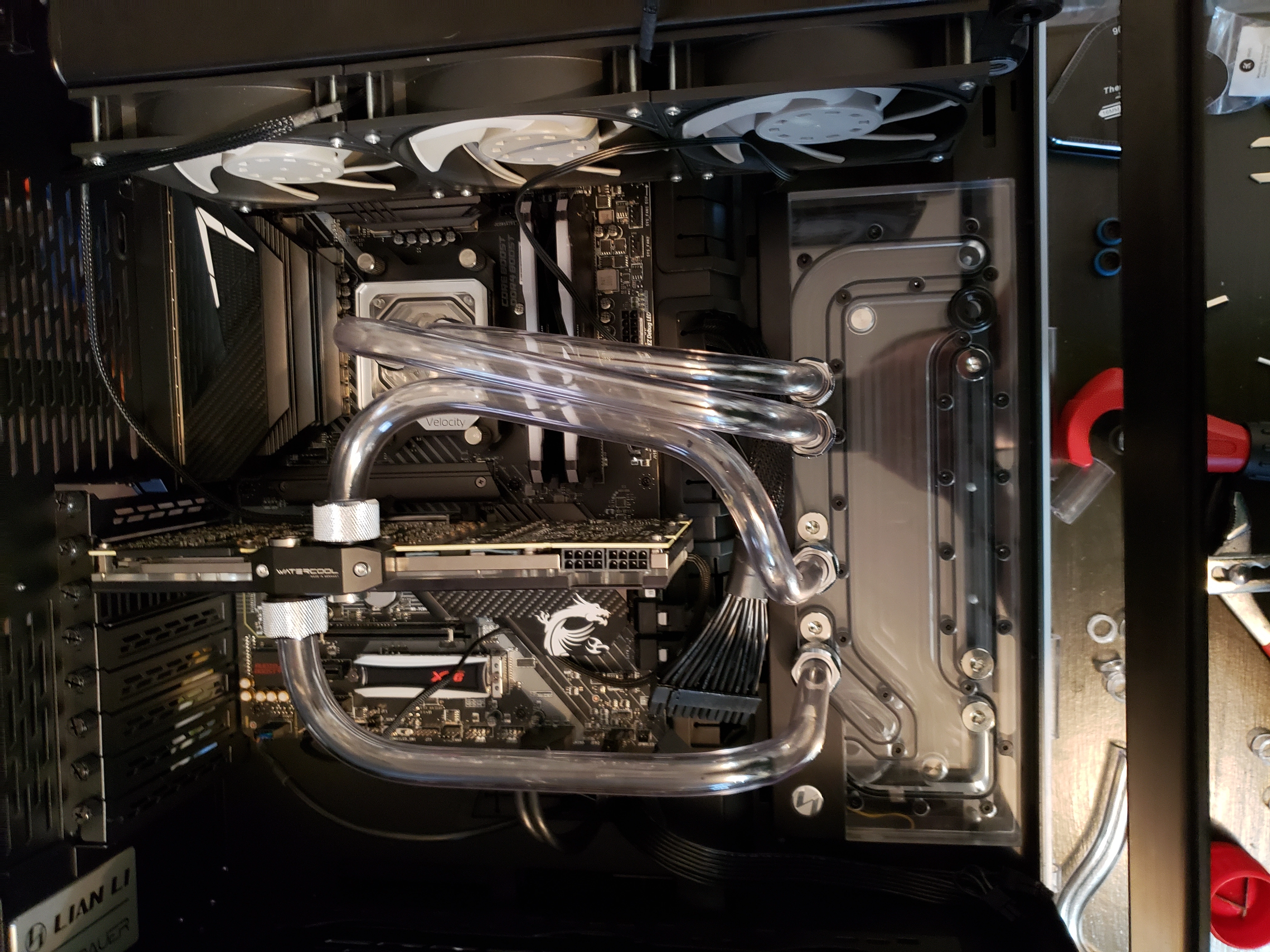

So, now I'll just show you my bends! I did the CPU first, and used that to align the distro plate:

I'm actually really happy with how this one turned out, I got in two pretty tight bends here I think! I then decided to do one of the bends for the rad, which I'm not really happy with, it looks pretty wonky and the other bend for the rad is going to be next to impossible...

I'm actually really happy with how this one turned out, I got in two pretty tight bends here I think! I then decided to do one of the bends for the rad, which I'm not really happy with, it looks pretty wonky and the other bend for the rad is going to be next to impossible...

I took a step back for a moment to think of what I could do next... that's when I realized something. I had been thinking the ports marked "Inlet" and "Outlet" on the distro plate meant that the fluid was moving In/Out of the plate, but it's actually from the reference of the component... SO I have my first CPU bend in the wrong port! And yeah, that does matter a lot!

So, I adjusted the distro plate such that the CPU bend that I like aligns with the correct port - this also put the rad in a position where I should be able to easily connect the two bends, awesome!

I'm getting pretty quick at the bends now, here's the first GPU bend:

I took a step back for a moment to think of what I could do next... that's when I realized something. I had been thinking the ports marked "Inlet" and "Outlet" on the distro plate meant that the fluid was moving In/Out of the plate, but it's actually from the reference of the component... SO I have my first CPU bend in the wrong port! And yeah, that does matter a lot!

So, I adjusted the distro plate such that the CPU bend that I like aligns with the correct port - this also put the rad in a position where I should be able to easily connect the two bends, awesome!

I'm getting pretty quick at the bends now, here's the first GPU bend:

I'm really happy with how this one turned out too!

Now, I did the next CPU bend... this one is actually really awkward:

I'm really happy with how this one turned out too!

Now, I did the next CPU bend... this one is actually really awkward:

I think there's probably a way better way to position this... but I think for now I'm going to leave it as is and maybe come back after I validate that I can get this thing running and re-run this one. It's good enough for now!

The issues from this cascaded when I did the next GPU bend:

I think there's probably a way better way to position this... but I think for now I'm going to leave it as is and maybe come back after I validate that I can get this thing running and re-run this one. It's good enough for now!

The issues from this cascaded when I did the next GPU bend:

It was really hard to get this bend in place due to the position of the last cpu bend, but I managed to get this one in. There is actually three bends involved in this one.

I actually like how it all turned out, but I really don't like how the three tubes are clumped together without any separation... I'll have to come back one day and do this again.

The two rad bends were very simple and only took me a few minutes now that I've got lots of practice:

It was really hard to get this bend in place due to the position of the last cpu bend, but I managed to get this one in. There is actually three bends involved in this one.

I actually like how it all turned out, but I really don't like how the three tubes are clumped together without any separation... I'll have to come back one day and do this again.

The two rad bends were very simple and only took me a few minutes now that I've got lots of practice:

And now, we're done the bending, for now at least!

It's time to leak test and fill!

And now, we're done the bending, for now at least!

It's time to leak test and fill!

Pressure Testing

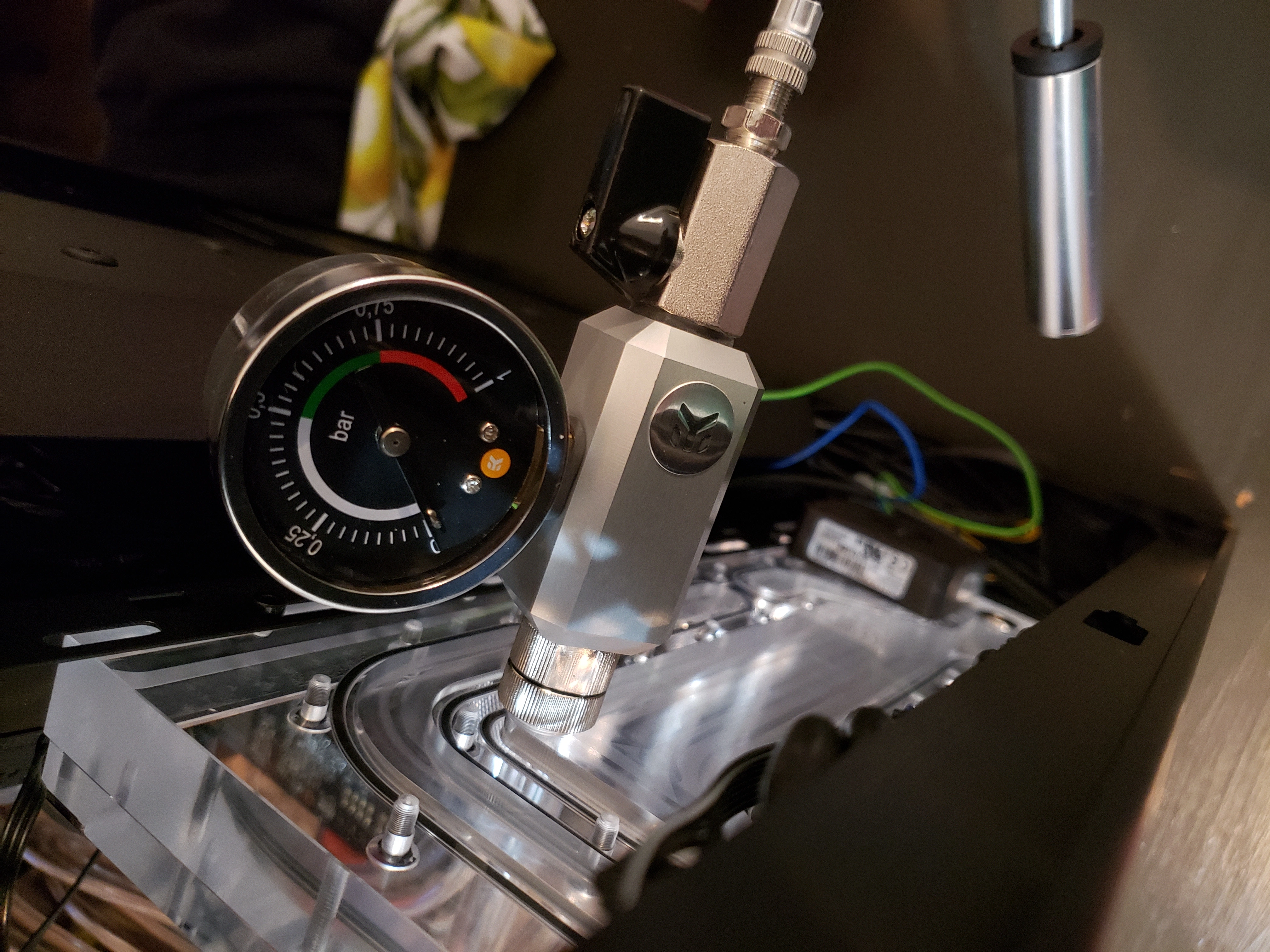

I spent the extra $100 to buy a pressure gauge to make this process a lot less scary, so I hooked that bad boy up to the loop and started pumping!

Uh oh, it's not holding pressure... I went around the rig and tightened all the fittings a little more and tried again:

Uh oh, it's not holding pressure... I went around the rig and tightened all the fittings a little more and tried again:

There we go! I left it like this and went for a night of drinking, and came back to see that it didn't lose any pressure, it should be good to go now!

There we go! I left it like this and went for a night of drinking, and came back to see that it didn't lose any pressure, it should be good to go now!

Filling

Onto the final part before I can turn it on! Watching fluid pour into this machine was incredibly rewarding:

The fluid was supposed to be electric-purple, but It honestly just looks Pink to me. Oh well, I don't really care.

Here's a little lapse of it filling up!

Oh yeah, and I actually didn't have any wire at home to create a jumper for the PSU, I know... an electrical engineer with no wire around seems insane, but It's a small apartment I don't have much here. So yeah, I pulled a big-balls move and connected my PSU's ATX power up to the MOBO just so I could switch the PSU on with my MOBO. Everything else was disconnected, but yeah, big balls. I just manually plugged in and unplugged the pump power while I filled it.

The fluid was supposed to be electric-purple, but It honestly just looks Pink to me. Oh well, I don't really care.

Here's a little lapse of it filling up!

Oh yeah, and I actually didn't have any wire at home to create a jumper for the PSU, I know... an electrical engineer with no wire around seems insane, but It's a small apartment I don't have much here. So yeah, I pulled a big-balls move and connected my PSU's ATX power up to the MOBO just so I could switch the PSU on with my MOBO. Everything else was disconnected, but yeah, big balls. I just manually plugged in and unplugged the pump power while I filled it.

Final Result

I'm pretty happy with the final result, I think I'll redo some of the bends in the future but for now I just want to enjoy this monster for a while!

Next Steps

- Buy a second rad, 3 more EK-Vardar fans and a 120mm case-fan for the back

- Buy an ARGB controller and 6 RGB fan shrouds for the Vardar's

- Redo a few bends